Product Categories

**IMPORTANT**

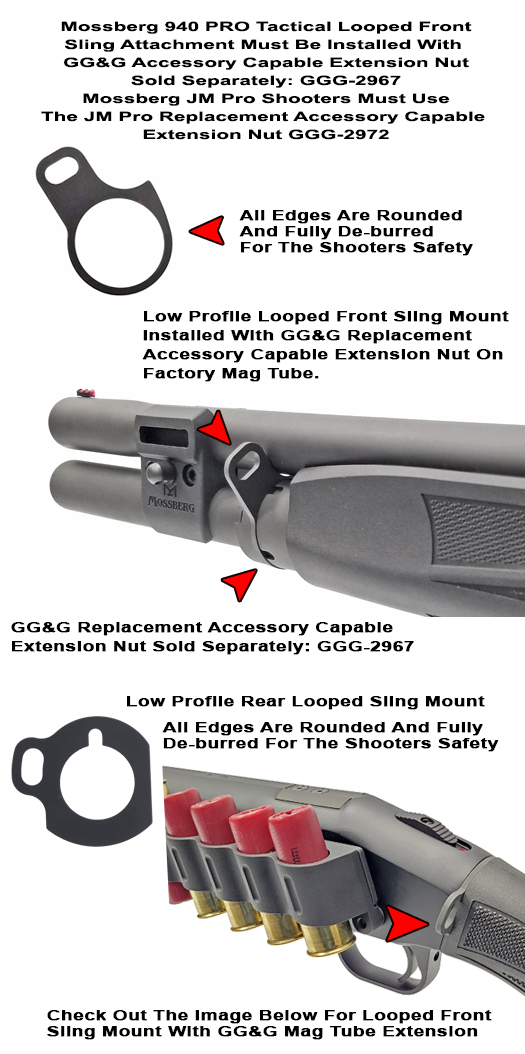

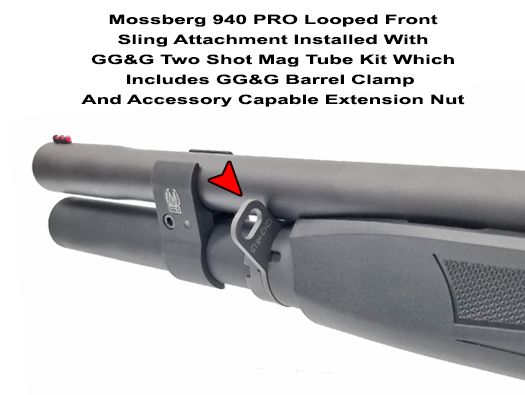

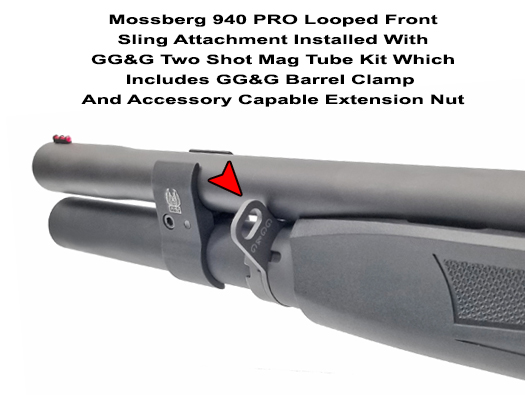

For Mossberg 940 PRO Tactical Shooters: The Front Accessory Can NOT Be Installed Without The GG&G 940 PRO Accessory Capable Mag Tube Extension Nut: GGG-2967.

For Mossberg 940 JM PRO Shooters: The Front Accessory Can NOT Be Installed Without The GG&G 940 JM PRO Accessory Capable Mag Tube Extension Nut: GGG-2972.

Ok, but what the heck is it, and why do I need it?

Here's what it is and why it is. Because of the Mossberg 940 PRO Tactical and 940 JM Pro forearm design and the relationship between it and the magazine tube extension nut, the standard method of front accessory mounting is not possible with the factory set up.

GG&G and our customers appreciate the Mossberg 940 PRO Tactical and 940 JM Pro shotguns and their features. However, it appears that Mossberg thought about the problem and offered an easy but incomplete and questionable solution.......A Plastic Barrel Clamp that accommodates M-LOK accessories. Our team of professional experienced shooters and advisers see at least two problems. One is the Plastic Barrel Clamp, it may not fail right away, but after multiple heat cycles and attempting to keep it tight on the barrel it will, in our humble opinion, lead to a failure. Number two is the M-LOK slot position being at the top of the barrel clamp. There is a reason that the majority of barrel clamp manufacturers, including GG&G, mount the sling or light mounts, whether they be an M-LOK configuration, or a more traditional screw attachment method, at the most stable position and most ergonomic position, the center point of the barrel clamp. As you pull on the sling, you are pulling the top non-anchored area away from the barrel. Occasionally it's a hot barrel - a very hot barrel, which tends to make plastic, even thermoplastics, more flexible and subject to degradation, bending and movement.

The GG&G Team came up with a very unique solution that works with multiple different accessories. Yes, you need the GG&G Replacement Accessory Capable Mag Tube Extension Nut in order to mount the front accessories. Yea, it is not an inexpensive solution, but it is manufactured from steel! Solid, Rugged And Dependable!

Need a sling for your Tactical Shotgun? We've got plenty to choose from - Choose Yours Here! Don't Miss Our Other American Made Mossberg 940 Pro Tactical Accessories And Related Products! Check Them Out Here!

Mossberg 940 PRO Tactical Looped Front And Rear Sling Attachment:

The GG&G Mossberg 940 PRO Looped Front And Rear Sling Attachment are designed, manufactured and tested to accommodate HK Style Snap Hooks or Mash Hooks. You get 10% off if you buy a GG&G Front And Rear Looped Sling Attachment combo package.

Mossberg 940 PRO Front Looped Sling Attachment Specifications:

- Easy to install on the 940 Pro or 940 JM Pro Shotgun equipped with the corresponding GG&G Accessory Capable Extension Nut.

- Will NOT fit the Mossberg 940 Pro Tactical SPX Model.

- Ambidextrous design for right or left handed shooters.

- Accommodates slings with Mash Hooks or HK style snap hooks.

- The 940 Looped Front Sling Attachment has smooth and rounded edges for shooter's safety.

- Material: Precision machined from tough A-36 steel. Not Stamped Sheet Metal.

- Finish: Manganese phosphate finished in non-reflective matte black per Mil-Spec.

- Weight: Less than 1oz.

- Warranty: Lifetime.

- Made In America By Men And Women Proud To Be Americans!

Mossberg 940 PRO Rear Looped Sling Attachment Specifications:

- Will also fit the Mossberg 940 Pro Tactical SPX Model.

- Installs easily with common hand tools.

- Accommodates slings with Mash hooks or HK style snap hooks.

- Ambidextrous design for right or left hand shooters.

- The 940 Looped Sling Attachment can be used as a single point sling or a dual point sling attachment.

- When used as a Mossberg 940 Single Point Looped Sling Attachment, it allows the operator to mount the weapon on either the primary or offside shoulder. As a result, during dynamic entries it becomes easier to “cut the pie" at doorways and move around corners, whether they are on the right side or left side, without telegraphing the operator's position. In addition, slings attached to a single point mount work especially well when operators are deployed wearing body armor or are involved in breaching operations.

- All edges dehorned and smoothed for shooter's safety.

- Material: Precision machined from 7075 aircraft grade solid billet aluminum alloy.

- Finish: Type III Hard Coat anodized non-reflective matte black per Mil-Spec.

- Weight: Less than 1 oz.

- Warranty: Lifetime.

- Made In America By Men And Women Proud To Be Americans!

![]()